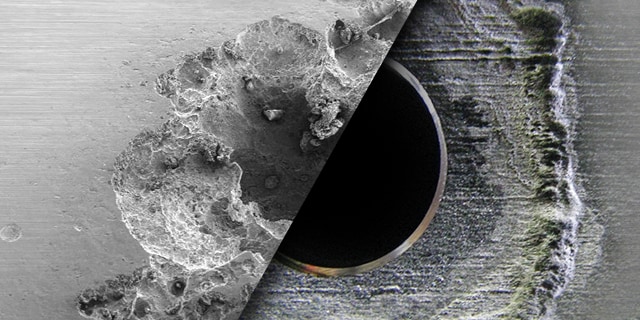

Pitting Corrosion vs. Crevice Corrosion: Identifying the Differences

Pitting Corrosion vs. Crevice Corrosion: Identifying the Differences

Corrosion – the deterioration of engineering materials, most commonly metals, by chemical interaction with their environment – is an extraordinarily costly problem. Just about every metal used to build our world corrodes, but only under certain circumstances.

There are steps to prevent corrosion in both oil and gas, and marine applications, which require a fundamental understanding of corrosion and what causes it.

In this week’s blog, Swagelok Company Senior Product Manager, Behram Ginwalla, discusses the main differences between Pitting and Crevice Corrosion, and how to identify and prevent corrosion in your tubing systems.

Read the full blog on the Swagelok Reference Point ->

A working ability among equipment and system operators to visually identify corrosion before it causes a bigger problem – and the ability to know where to look for hidden corrosion – can both minimize risk, and in many cases save significant amounts of time and money.

Swagelok can help – we’ve been fighting corrosion since 1947, and we’ve transferred our knowledge to a new Materials Selection Guide designed to help you make informed choices that reduce corrosion.

Explore Material Selection GuideHelpful Reference Materials