Design and Assembly Services

Take the Building and Testing of Fluid System Assemblies Off Your To-Do List

If you’re short on trained personnel or simply short on time, Swagelok-trained technicians can provide an extra set of hands by fabricating your fluid system assemblies for you. You will receive a professionally designed, repeatable solution, with testing, inspection, and packaging included—all covered by Swagelok’s Limited Lifetime Warranty.

We call these assemblies Swagelok® Custom Solutions. Custom Solutions can be small or large assemblies, consisting of a few components or a complete panel or enclosure. They always include high-quality fluid system components, but we can also incorporate wiring, automation, transmitters, relays, pumps, and more. Whatever your parameters, rest assured that you’ll receive only the highest-quality assemblies, panels, or enclosures when you choose Swagelok® Custom Solutions.

Save Time With Standard and Configurable Assemblies

Design, fabrication, and assembly specialists at Swagelok technology centers and local Swagelok sales and service centers have worked with businesses across the globe to add efficiency and reliability to their operations by delivering dependably designed and constructed fluid system assemblies. Standard Swagelok assemblies include:

Grab Sampling Systems

Swagelok® grab sampling systems allow for safe, efficient sample capture and are available in a variety of configurations and advanced features.

Ammonia Sampling Systems

The Swagelok® ammonia sampler makes anhydrous ammonia sampling safer by minimizing operators’ exposure to liquid and vaporized ammonia.

Gas Distribution Systems

Standardized, configurable Swagelok® gas delivery systems help protect operators, increase process uptime, and improve process accuracy.

Mechanical Seal Support Systems

Swagelok® seal support systems are guided by API 682 and are offered as kits and assemblies and are designed to maintain seal longevity.

Analytical Subsystems (PrESS)

Pre-engineered and preassembled fluid sampling and control subsystems minimize system footprints, simplify design, and promote accurate sampling.

Receive as Much Design Support as You Need

Fluid system design professionals are prepared to assist throughout the solution development process. We can follow your existing design, or you can work with global tech centers to develop a new or revised one. In any case, our approach is collaborative, as we work closely with you to ensure we understand the problem and are developing the configuration that most completely meets your needs.

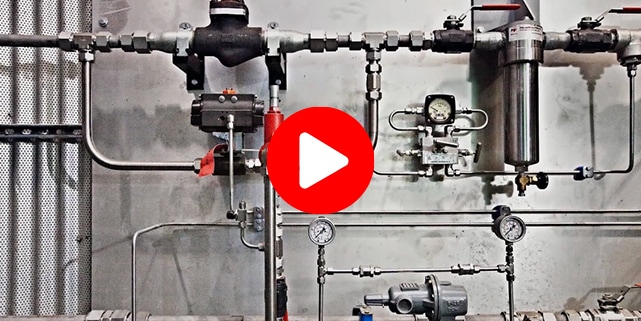

A Look at Swagelok Design and Assembly Services

Hear how Swagelok design, fabrication, and assembly specialists can help you add efficiency and reliability to your operations.

Whether you have a preliminary drawing or just an idea, reach out for:

- CAD drawings

- Piping and instrumentation and diagram (P&ID)

- Component selection and sourcing

- Bills of materials (BOM)

- Professional services, such as bending and welding

- Testing of system performance

- Professional packaging and delivery

You trust our components. Now trust our experts to create great fluid system assemblies.

Contact our Swagelok Vietnam hotline: +84 (0) 936 42 0804 or email to: sales@swagelok.com.vn. ![]()

Case Study: Fluid System Evaluation Leads to Production Continuity for Manufacturer

Customer

Manufacturing company

Challenge

“How do we discover leaks early to avoid scrapping assemblies?” A company was forced to scrap $12,000 worth of assemblies because leaks were discovered too late in production, leading to loss of revenue and reputation with customers.

Need

Assistance finding the reason for the leaks, improving quality assurance, streamlining production processes, and eliminating product and labor waste.

Solution

- Swagelok field engineers identified the root cause of the assembly leaks was due to intermix/interchange of fittings

- Leak-tight, fabricated subassemblies were provided through the Swagelok Custom Solutions program

Result

- The company avoided a two-month backlog in production that would have resulted in 100 fewer units being manufactured, equaling $800,000–$900,000 in losses

View Our Customer Success Stories

Rosendahl Nextrom Optimizes Quality and Production Efficiency

Rosendahl Nextrom relies on the quality of Swagelok products to ensure system purity and leak-tight performance and Swagelok training services to expand the knowledge of its staff.

Shenyang Blower Works Enhances System Performance and Safety

Hear how Shenyang Blower Works Group Corporation’s use of Swagelok design and assembly services helps to increase the quality and consistency of its equipment while significantly lowering maintenance costs for customers.

New Flyer of America Counts on Swagelok to Reinforce Innovation and Manufacturing Efforts

Learn how Swagelok design and assembly services played a role in helping ensure the quality and reliability of heavy-duty transit bus fuel systems.

Charbonneau Industries Speeds Production With Swagelok Design and Assembly Services

Discover how Charbonneau Industries uses Swagelok Custom Solutions to speed production, reduce labor costs, and secure system quality and reliability.

Green Alternative Systems Manufacturing Starts at Swagelok Design and Assembly Services

Learn how collaboration with Swagelok helped Green Alternative Systems accelerate production, lower labor costs, and achieve greater system reliability.

HOERBIGER Engineering Services Secures Reliability With Swagelok Design and Assembly Services

Consider the satisfaction HOERBIGER Engineering Services realized with the incorporation of highly reliable Swagelok-designed and assembled subsystems in its large-bore engine system upgrades.