Design & Build - Panel Masters

Swagelok Design & Build – Panel Masters

We’re your local Design & Build resource for safe, premium-quality, leak-tight Sub-Assemblies, Assemblies, Enclosures, Skids, and more. All expertly constructed and tested by Swagelok-certified technicians – with all products warrantied by Swagelok Company.

We're your local Swagelok Applications Solution for advancing your Fluid-System safety, performance, and profitability!

|

|

|

|

|

Our Custom Fabrication Services Include:

|

We can help you save time, money, and worry when your production schedule is tight. State-of-the-Art, 5,000-square-foot Working and Staging Area 5-ton Overhead Crane, with 18-foot clearance Our Fab Shop Also Provides:

|

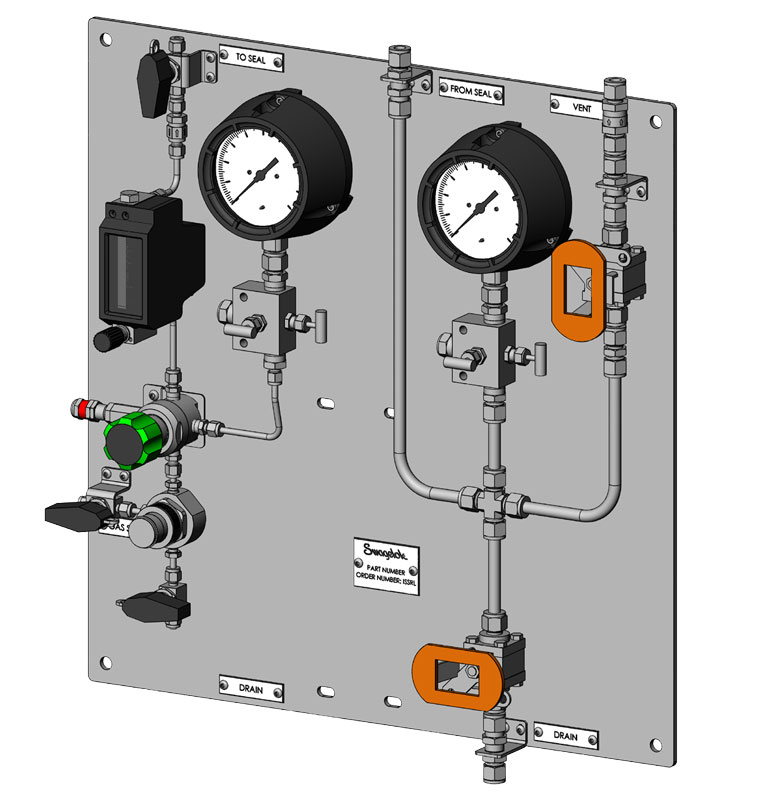

Grab Sampling Systems

|

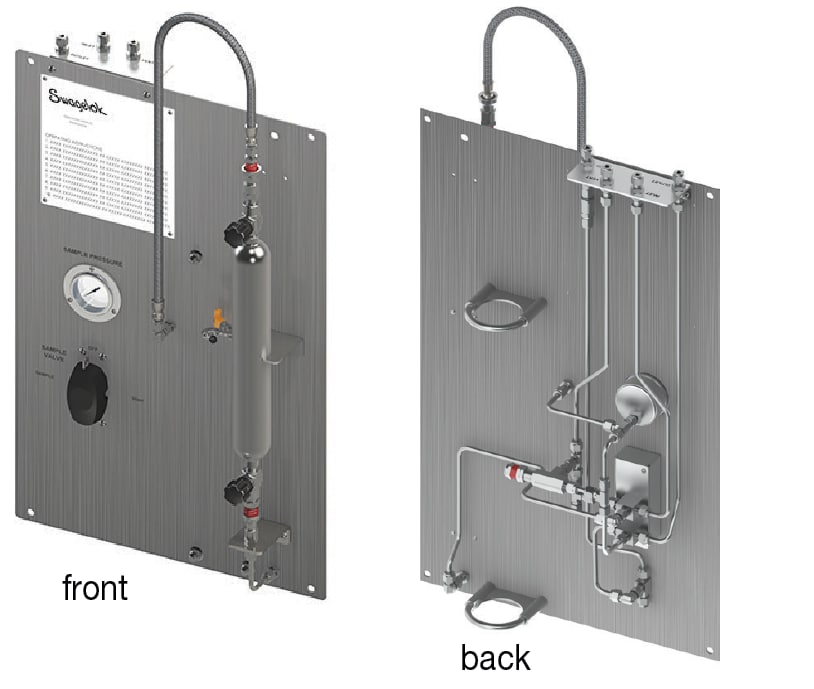

GSM: Grab Sample Module

GSM panels feature a switching valve configuration with two or three Swagelok 40G series ball valves, facilitating simultaneous control of fluid routing. These configurations reduce the number of overall steps required for sampling and give a clear indication of sequencing to the operator, reducing the likelihood of errors. |

|

|

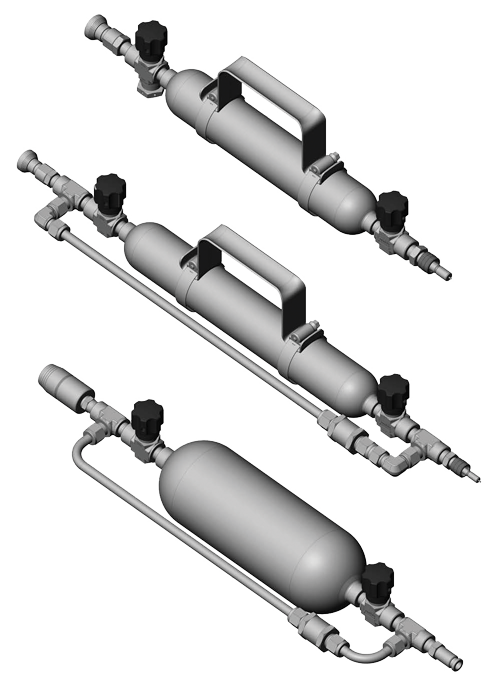

GSC: Grab Sampling Cylinders

|

|

|

GSL: Grab Sample Liquid

|

|

|

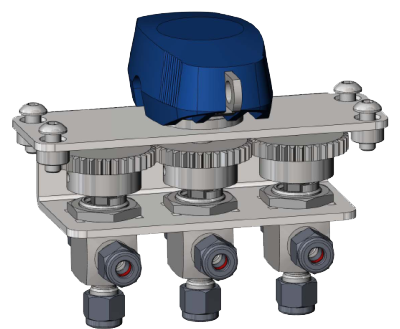

Swagelok Grab Sampling Valve

|

|

Gas Distribution Systems

Designed to ensure minimal leakage and maximum operator safety. All components are clearly labeled for ease of operation.

- Substantially reduce potential for gas leaks

- Optimize gas usage

- Fully assembled and tested to ensure reliability and reduced maintenance

- Covered by the Swagelok Limited Lifetime Warranty

Offered in four standard panel designs that safely, effectively, and efficiently get gases from a high-pressure source to where they need to go – at the required pressure and flow rate.

|

SSI for Three Bottles |

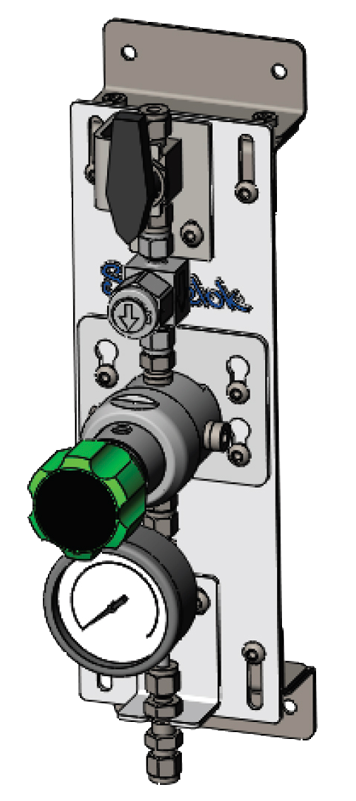

SCO with Outlet Pressure Regulator |

|

SGP Single Stage |

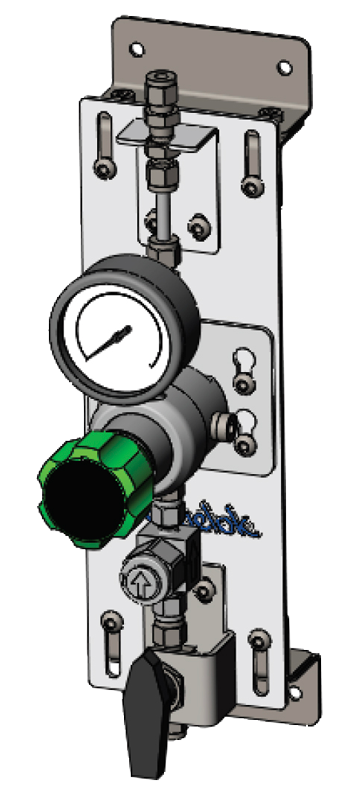

SGP Dual Stage |

SPU with Top-to-Bottom Flow |

SPU with Bottom-to-Top Flow |

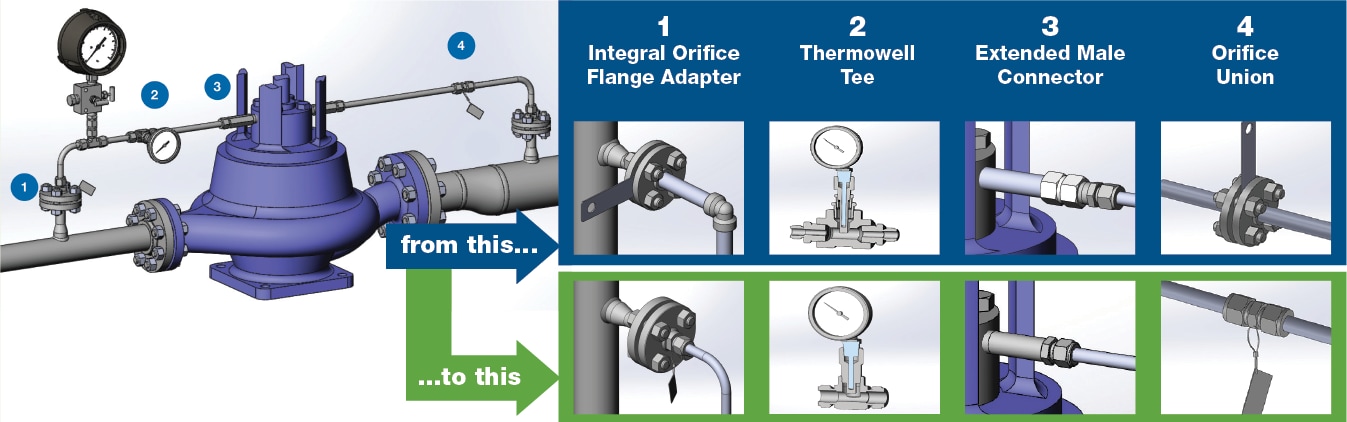

Mechanical Seal Support Systems

Offered as easy-to-install kits or assemblies – and available in multiple API Plan configurations, our designs feature the minimum arrangement of components as specified by API 682. No pipe threads and limited number of overall connections results in significantly less chance of leakage.

|

Seal Plan Kits A collection of components that are used to help ensure the support system is properly installed or connected to the pump. Some API plans are detailed only as a kit of components that are ready for field installation due to the simplicity of the arrangements. Seal Plan Assemblies

Panels, seal pots, or skid systems that comprise most of the API seal support plans. Ordering and numbering structure means users can select a variety of configurations and additional system components to meet specific site or application requirements. |

|

- Integral Orifice Flange Adapter: Replace threaded or welded flange assemblies with a one-piece flange adapter with integral orifice.

- Thermowell Tee: Reduce threaded connections and monitor temperature with integrated thermowell pre-welded into tube fitting tee for ease of installation.

- Extended Male Connector: Eliminate threaded pipe and potential leak points with a single fitting. Available in 4-inch and 6-inch lengths so you can clear the shroud and go straight from the gland to your tubing run in one piece.

- Orifice Union: Easily add an orifice to a flush system. This fitting makes welding bulky flange assemblies unnecessary. Tagged for visual identification.

Configurable Plans

All Swagelok seal support plans are easy-to-use/maintain and are designed for ultimate safety and performance according to API 682- recommeneded best practices.

|

Atmospheric Plans |

Between Seal Plans |

Process Side Plans |

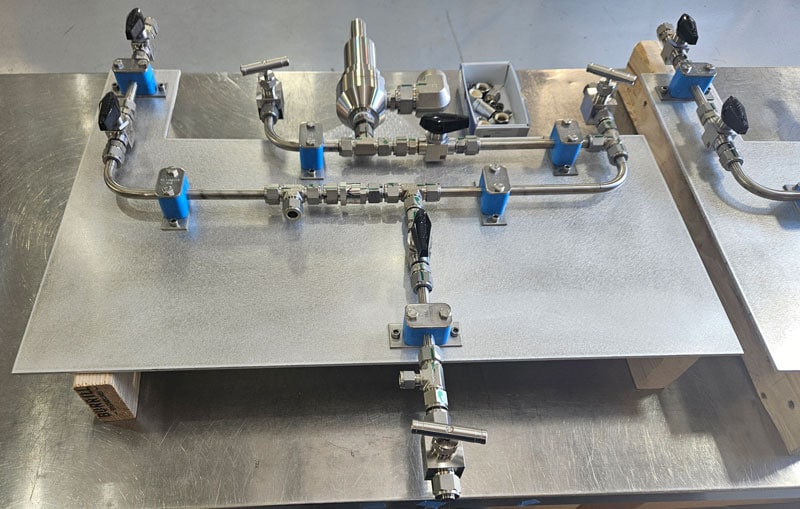

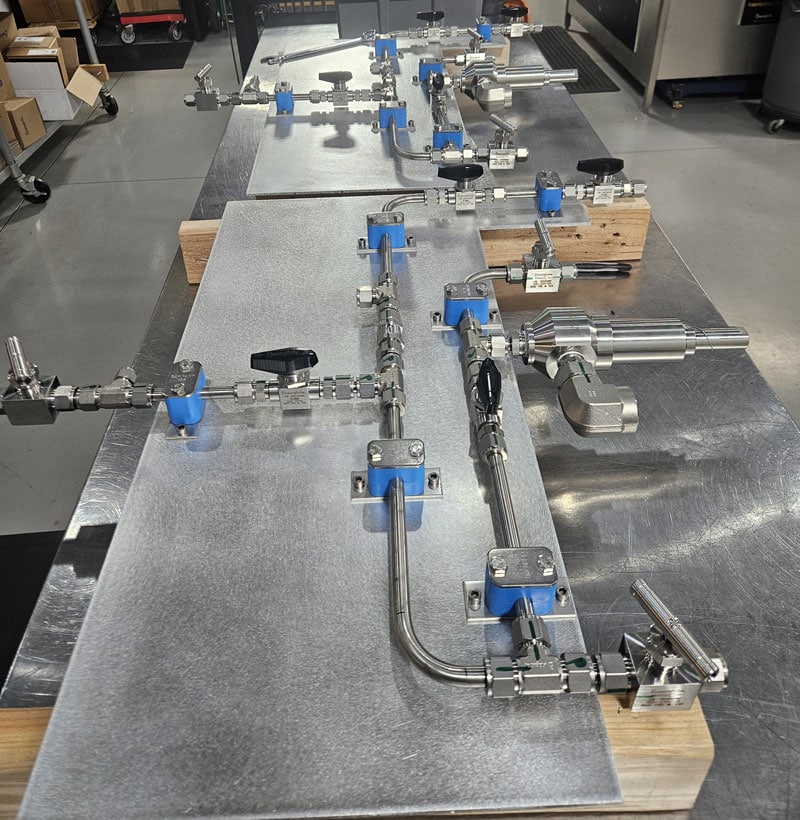

Here Are a Few of Our Recent Design & Build Custom Fabrication Panels

|

|

|

|

You trust our components; now trust our experts to create the best fluid system assembly you can have. Contact Swagelok Pittsburgh | Tri-State Area today to learn more about how we can help you with our custom solution services.

View the full range of Swagelok Pittsburgh | Tri-State Area's Strategic Service Offerings.