Best Practices for Gas Sampling Systems and Methods

A Practical Guide to Gas Sampling Methods

Matt Dixon, Senior Principal Design Engineer, Swagelok

Optimizing your chemical processing costs and maintaining high-quality product outputs require regular capture of representative process fluids for laboratory analysis. Grab sampling—also called spot sampling, field sampling, or just sampling—helps validate process conditions and verify that the product you are making meets internal or customer-based specifications. Grab sampling can also help verify readings of online analyzers, an increasingly popular way to obtain real-time insights into your process.

Gas grab sampling presents a unique set of challenges that operators must overcome to in order to obtain an accurate portrait of true process conditions. Read on as we explore these challenges and how to overcome them with the right techniques.

Basic Rules for Gas Sampling

Adhering to few basic rules can help ensure that gases and volatile liquids are collected and maintained at temperatures and pressures that inhibit phase changes, which can alter the samples’ composition. Keep these rules in mind:

- The sample must represent the process. Use probes to draw gas samples from the middle of the process pipe and avoid phase changes during sample transportation.

- The sample must be timely. Minimize transport time from the draw point to the laboratory to help ensure process conditions are accurately represented. The sample must be pure. Avoid dead legs upstream of the gas sample container and allow for adequate purging and flushing of the gas sampling system to minimize the potential for contamination.

- Sampling must be safe. Gas sampling inherently involves a human operator interacting with process fluids, which often can be harmful if direct contact occurs. For this reason, following best practices and using well-designed gas sampling systems are essential not just to sample accuracy, but also to operator safety.

- Sampling gases and volatile liquids involves different considerations than sampling nonvolatile liquids.

How to Choose a Sample Cylinder

Because gases and volatile liquids are more susceptible to phase changes and must be kept at pressure for accurate analysis, it is necessary to use sample cylinders (as opposed to less-expensive, unpressurized sample bottles) for collection and to preserve sample representativeness. Gas sample cylinders are also highly effective at protecting sample technicians and the environment from fumes or emissions if the gas is toxic.

Most sample cylinders are made with seamless tubing for consistent wall thickness, size, and capacity, but there are some variables to consider based upon your specific sampling needs. You can work with your cylinder supplier to choose the appropriate type.

A few features to consider seeking out when choosing cylinders include:

- Easily operable quick connects, allowing for efficient and safe connecting and disconnecting from your sampling point

- A smooth internal neck transition, which can help eliminate trapped fluid and makes cylinders easy to clean and reuse

- Overpressure protection, which can provide higher levels of operator safety. Rupture and relief valves are available in a tee or may be integral to your cylinder’s main valve.

- Proper material composition and finish, as special alloys or materials may be required depending upon the gas or volatile liquid being sampled

- Incorporated bypass lines, which can be beneficial for purging toxic sample remnants and enhance technician safety. A bypass line allows the purge fluid to flow through the quick connects, ensuring that if spillage occurs when the cylinder is disconnected, the spill is composed of purge fluid rather than the toxic sample.

- Durable design and construction. Sample cylinders must often be transported considerable distances for laboratory analysis.

How to Properly Fill a Sample Cylinder

To fill a sample cylinder correctly, it is usually most appropriate to have the cylinder in a vertical orientation. There are a few reasons why.

If sampling a volatile liquid, it is best to fill the cylinder from the bottom to the top. This allows any trapped gas that may be in the cylinder to be flushed out of the top as it is filled, typically through an outage tube. An outage tube also allows the cylinder to maintain some amount of vapor space—a cylinder that is completely filled could potentially rupture in the event of an unexpected change in temperature. Conversely, when sampling gases, cylinders should be filled from the top down. This allows any condensation that may have formed in the line to be flushed out through the bottom.

How to Maintain Sample Cylinders

Regular, proactive sample cylinder maintenance is a must for any sampling-centric operation. Like any piece of industrial equipment, sample cylinders are prone to regular operational wear and tear, and damaged or malfunctioning cylinders can present a safety issue for staff and may compromise the accuracy and integrity of your sampling practices. To mitigate these effects, at minimum, sample cylinders should be subject to an annual inspection and pressure test. Every five years, they should be recertified.

Damage can occur between those inspections, however. Some of the most common issues to watch for include:

- Leakage across key components, including valves and quick connects

- Corrosion resulting from compatibility issues with the sample

- Internal surface conditions, absorption

- Improperly installed components

Learn more about gas sampling containers.

Minimize Gas Sampling Errors

By necessity, gas sampling involves a technician physically drawing a sample from the process—this inherently introduces the potential for human error into your process. Luckily, there are a few different strategies to limit these errors.

Gas Sampling System Documentation

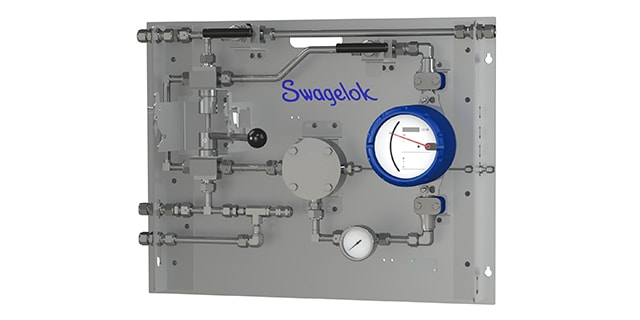

Gas sampling panels may be available with an engraved placard on the panel, which can contain helpful details on how to operate the panel, as well as how to order replacement parts if necessary. Instructions make it easier for any technician to draw a sample, even if they have not operated the panel before. Parts documentation makes it easier to notify your supplier of exactly what you need with no guesswork required.

Proper Sample Cylinder Orientation

Geared Valve Assemblies

These ensure that all valves required to collect a sample are activated in the correct sequence. These can contribute to safe sample collection by eliminating the need for the operator to open and close those same valves manually. A purge function can also be incorporated into a geared valve assembly, ensuring that purge fluids cannot be reintroduced into the main process due to human error.

Automated Sample Collection

Automating sample collection, while coming at a higher upfront cost, can further reduce human error. An automated panel can ensure the enclosure door is closed properly, that valves are opened correctly and in sequence, and that product and purge flow and pressure are precisely maintained. This can generally be accomplished by wiring your grab sampling panels into a programmable logic controller (PLC) or the plant control system. Be sure to check your hazardous area requirements anywhere you are adding wiring.

Ultimately, gas sampling should be a process that gives you greater confidence that you are providing a high-quality, up-to-spec product for your customers. Choosing easy-to-use, well-designed gas sampling systems and following established best practices throughout your facility can contribute to that goal.

Interested in learning more about how to enhance gas sampling practices in your facility? Swagelok’s sampling specialists can help you evaluate your sampling needs and assist you in choosing a system that is right for you.

Gas and Grab Sampling Articles

What is Grab Sampling?

Master grab sampling best practices for accurate results in both gaseous and liquid media. Understand the characteristics of a well-designed system.

Liquid Grab Sampling Strategies to Control Costs

Discover several strategies to help drive down costs and minimize errors in your liquid grab sampling processes as you validate process conditions and analyze end product quality.

Sample Probe, Calibration & Switching Modules + More to Simplify Sampling

Learn how standard pre-engineered subsystems can bring efficiency and consistency to your operations by reducing the manual installation and assembly of multiple parts.