“I’m under pressure to maintain the reliability and overall health of my sampling systems.”

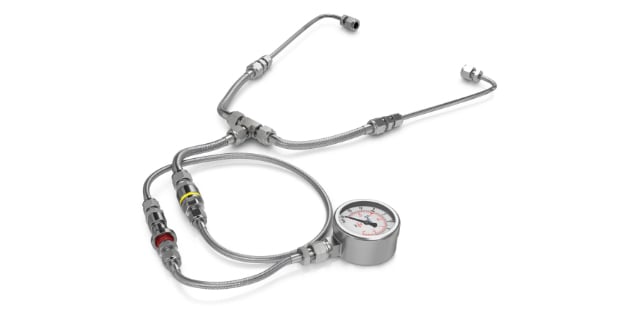

Producing a timely, compatible, and representative sample for analysis every time at the lowest overall cost is complicated. Suboptimal system designs or slight delays can threaten the accuracy of your sampling systems or lead to damaged equipment, unusable process fluid, or upset customers.

Our Solution: We provide sampling system evaluation and optimization services, analyzing your sampling systems from the process tap to the analyzer before offering targeted recommendations to help you improve system design to attain more representative samples, reduce time delay, and improve analyzer compatibility.

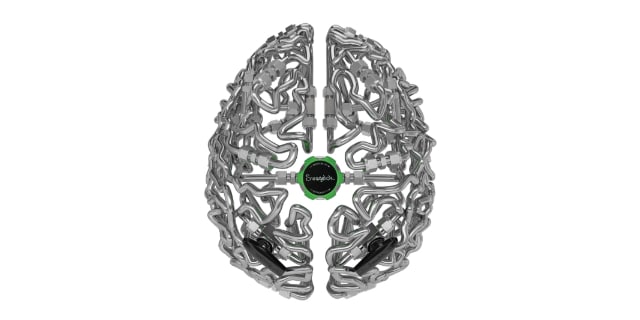

“I’m under pressure to retain critical sampling system knowledge at my company.”

Designing sampling systems and subsystems that efficiently provide precise, representative samples requires highly specialized knowledge and experience. As up to 50 percent of skilled workers retire in the next 10 years and others change jobs, it’s important to take step to help your team maintain critical sampling knowledge—and ensure you are familiar with best practices yourself.

Our Solution: We provide sampling system training courses that address the complexities and underlying design principles of sampling systems and their subsystems, helping you and your team attain the knowledge necessary to develop reliable systems.

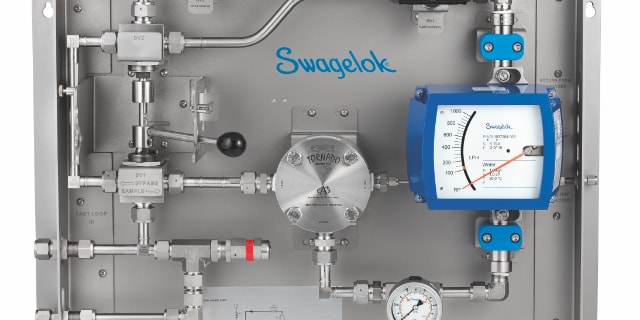

“I’m under pressure to constantly balance resources to meet the needs of the business.”

Conflicting job responsibilities may take you or your team away from designing and assembling sampling systems or tending to analytical instruments, but these critical quality-control systems are still important to maintaining process integrity. If you don’t have the time or resources available to complete sampling system-related projects on time and on budget, expensive system downtime could follow.

Our Solution: We provide design consultation and assembly services meant to take strain off you and your team. Let our sampling system experts provide the reliable assemblies and design support you need to feel confident about your sampling results.

Learn more about locally available support.

You know Swagelok as a trusted supplier of high-quality fluid system components. But we can help alleviate some of the technical and engineering-related pressures you face each day. Interested in learning more? Fill out the service request form linked below for more information.

Dig deeper. Explore resources developed for people like you.

Case Study: Swagelok Application Expertise Aids in Petrochemical Safety for INEOS

Learn how Swagelok engineers worked with INEOS, a global petrochemical manufacturer, to bolster analytical instrumentation and component selection expertise among the INEOS team.

4 Areas to Inspect When Measuring Time Delay in Sampling Systems

Delays between the moment samples are grabbed and when that sample is analyzed are unavoidable, but underestimating that delay can negatively affect process control. Learn to recognize your delay sources.

Grab Sampling 101: Reducing Plant Costs

When producing a product with a precise chemical composition, an accurate sampling process is critical to plant production. Learn how to implement a grab sampling process to minimize overall costs.