7 Tips for Industrial Fluid System Handling

7 Tips for Building Safer Industrial Fluid Systems

Ken Backus, Field Engineer, N. America

In an industrial plant or refinery, potential safety risks lurk around every corner. As a plant manager, one of your primary responsibilities is to reduce those risks to not only ensure safety, but also maintain uptime and preserve a steady revenue stream at your facility.

One critical area of focus is your plant’s industrial fluid systems. Such systems often transport high-pressure and high-temperature fluids and gases that can increase health, safety, and environmental concerns if something goes awry. Fluid system failure is not an option. Fortunately, your engineers and technicians can implement a variety of strategies to preserve the safety of your fluid systems, particularly during design.

1. Never Mix Components from Different Manufacturers

All industrial components are not created equal. Interchanging and intermixing components made by different manufacturers can result in unpredictable performance, environmental releases, safety problems, and increased costs. For example, half-inch fittings from different manufacturers may not have the same tolerances. Combine the two, and you may introduce an increased potential for leaks or even a dangerous blowout.

Obtaining a leak-tight seal that will withstand high pressure, vibration, vacuum, and temperature changes depends on exacting tolerances, meticulous quality control, and time-tested design principles. Your best bet is to choose a consistent, reliable component supplier with quality products manufactured to rigorous standards. Using the same manufacturer for every component within your fluid system will ensure compatibility throughout your system operations.

2. Minimize Opportunities for Human Error

Mistakes can occur even within the most well-trained teams. However, there is plenty you can do to minimize the potential for human error by following safety-minded fluid system design principles. Start off by devoting time to consistent component labeling. You can mount detailed tags on your equipment and hoses to indicate what takes place within that system, allowing operators to make careful adjustments. You can also color code handles, tubes, and pipes throughout your plant, so workers can immediately identify what types of fluids or gases are flowing through them—reducing room for error.

Another useful strategy is to install additional components to minimize the risk of accidental contact from moving objects or people. Even better, add a lockout on a critical process valve to prevent accidental actuation while eliminating safety concerns.

3. Use Ideal Components for the Job

When plant safety is your highest priority, it is rarely worth the risk to make a price-based decision when purchasing fluid system components. You will not be able to justify minor component savings if that part leads to a costly safety event.

Instead, rely on brands with a proven reputation and track record in your application. Selecting ideal components requires a complete understanding of process conditions. For example, if your fluid system generates a static charge, you want to use a hose with a conductive metal core, or a PTFE core with carbon black, to dissipate static rather than discharge it through the hose’s core. This material selection will help prevent future leakage. Also, be sure to only purchase components through trusted partners and authorized channels, as counterfeit and substandard inventory can harm your system operations and overall plant safety.

4. Reduce Complexity Wherever Possible

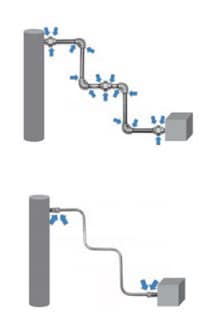

Reducing fluid system complexity wherever possible will help you minimize potential complications. Simplifying systems also enables maintenance efficiencies, as technicians can troubleshoot problems more easily with fewer components to analyze. For example, consider changing piping runs to bendable tubing instead to reduce potential leak points.

The pipe assembly above has seven fittings and 17 potential leak points.

In comparison, the tubing below has just two fittings and four potential leak points.

Additionally, your team could remove complexities from your system operations altogether by having a supplier build custom fluid system assemblies for you. Whether an assembly consists of a few components or a complete panel or enclosure, there is room for error when piecing these parts together. A supplier that can repeatedly build high-quality assemblies, backed by a warranty, will take any guesswork out of your team’s hands—and provide peace of mind that the assembly is leak-tight.

5. Follow Manufacturer’s Instructions Carefully

Failure to follow documented fluid system assembly and disassembly procedures might seem like a minor mistake, but it can lead to major consequences. The best practice is to follow the manufacturer’s installation steps to avoid common errors, such as:

- Under-tightening fittings, which creates opportunities for leaks and blowouts

- Not ensuring tubing rests firmly on the shoulder of the tube fitting body before tightening

- Failing to properly check tubes for ovality, defects, or scratches that can compromise a seal

- Failing to check extremes of wall thickness against fitting manufacturers’ suggested limitations

- Failing to use a proper gap inspection gauge to ensure sufficient fitting pull-up

6. Factor for Vibration and Motion in Designs

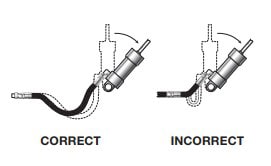

When assembling a de-energized industrial fluid system, it can be easy to forget about the effects of machine vibration. Your team will need to account for this factor in their system designs to avoid damage to tubing or fittings—potentially causing components to leak. Add proper supports to ensure tubes and fittings will not become fatigued during high-pressure usage. Additionally, your team should allow for a proper range of motion for moving

In some cases of intense vibration, you may consider switching to a hose, which may absorb the vibration better than tubing. When using a hose in a motion application, distribute movement over a sufficient length to prevent any bends that are smaller than the hose’s minimum bend radius. Too small of a bend can lead to premature hose failure. Hoses need to be replaced over time, so ensure that component life is taken into design considerations as well.

7. Account for Tubing Hardness and Material Compatibility

To guarantee a leak-tight fitting connection, it’s important that fluid system tubing materials be compatible with each other and have the appropriate hardness to stay connected. Metal tubing should be softer than the fitting components—effectively gripping the tube. For example, avoid using brass fittings with stainless steel tubing, as the fitting material is too soft to provide a sufficient hold on the tube.

While the above steps may appear to be simple, they’re often overlooked in most facilities. Ensuring your team keeps best system design and installation practices top of mind will help your plant operations stay on track. It is also a good practice to offer your team training opportunities and refresher courses. Taking appropriate precautions and following sound fluid system design principles can help to prevent costly errors and enhance plant safety in the long-term.

Related Articles

Your Industrial Fluid System Safety Checklist

Follow these best practices to enhance the safety of your industrial fluid system.

Refinery Safety Depends on Well-Trained, Empowered Employees

Fugitive emissions of hazardous gases can occur in refineries. Safe, leak-free containment depends on knowledgeable and empowered teams.

3 Reasons to Audit Your Offshore Fluid System

Evaluation and advisory services for your offshore platform can reveal hidden leaks or other potential safety and performance issues.