What to Look for In Hydrogen Valves

High-Performance Hydrogen Valves: What to Look for When Making a Selection

Chuck Hayes, Principal Applications Engineer for Clean Energy, Swagelok

Hydrogen fuel is growing quickly as a mobility solution. It has proven itself safe, cost-effective, practical, and sustainable. In short: it’s the ideal avenue for

Hydrogen is the ideal avenue for transportation’s future.

To fulfill this potential, hydrogen vehicle and refueling infrastructure must be designed and built with high-quality materials in order to deliver leak-tight performance that will need to last for years or even decades. And not just any components are up to the task. The production and handling of hydrogen fuel comes with its own unique set of challenges, thus demanding a specific set of performance criteria from components throughout a hydrogen fuel system.

Valves—responsible for controlling the flow of hydrogen in vehicle or stationary systems—are a good example. How can you be sure you’re selecting and specifying a valve that delivers performance suitable for hydrogen service? Read on to find out.

Why High-Performance Matters in Hydrogen Valves

Why High-Performance Matters in Hydrogen Valves

Operating conditions for hydrogen fuel systems are inherently challenging. When specifying hydrogen valves, considerations must include:

- Pressures. To achieve desired density, H2 must be stored in on-vehicle tanks at 350 – 700 bar

- Stress and vibration. Systems must be able to withstand fast speeds, bumpy roads, and inclement weather conditions

- Safety. Refueling stations must be safely operable by the average consumer

- Maintenance. Ability to easily remake leak-tight joints during servicing

All hydrogen valves should offer performance levels that meet those requirements. They should demonstrate leak-tight performance at the connection point and at their shutoff or regulation point, with the ability to withstand the necessary operating conditions inherent to hydrogen applications.

What Makes Hydrogen Different?

Hydrogen molecules are among the smallest in the natural world—and that means containing them can be challenging.

All connection points in hydrogen systems must be leak-tight. Any escaping gas can pose a safety risk, especially when end-users interact with a dispenser during refueling. Leaking gas in cars or storage systems is also wasteful.

And because hydrogen molecules are so small, they can in fact diffuse into lower-quality stainless steels. This phenomenon is known as hydrogen embrittlement. Over time, pressure can produce fissures in the material, which can become highly problematic in hydrogen service.

Hydrogen Ball Valves

Hydrogen Ball Valves

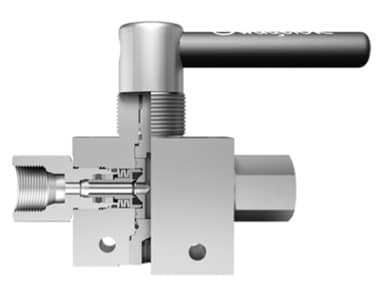

Ball valves are a common component found in hydrogen systems, used to start and stop the flow of hydrogen from one direction to the next. When selecting ball valves for hydrogen applications, it is important to look for stem seal designs that are highly resistant to wear. A good option may incorporate a trunnion-style ball with a direct-load design, which helps to enable leak-tight performance with every activation and shutoff. A bottom-loaded stem design can also reduce any potential stem blowout, offering enhanced safety.

When in doubt, your valve supplier should be able to help guide your selection. Applicable ball valves may offer 2- or -3-way functionality, different mounting options, and a range of flow coefficients depending on the needs of your system. Finally, look for good compatibility with fittings that are designed specifically for hydrogen applications.

Hydrogen Needle Valves

Hydrogen Needle Valves

Needle valves are used to make relatively fine adjustments in the amount of fluid flow. In hydrogen applications, some important considerations must be made when specifying them. Needle valves are typically all-metal in construction, requiring a large amount of force to seal properly. Such a force has the potential to deform the needle itself and possibly the seat, creating a potential hazard and requiring costly maintenance. Further, such required force typically necessitates the use of large air actuators to open and close the valves, which can take up to two minutes to fully actuate.

With these things in mind, it is important to look for needle valves that are made from high-quality 316 stainless steel that can resist deformation during repeated use. Also, keep in mind that not all needle valves are properly pressure-rated for common hydrogen applications (350/700 bar); choose a needle valve that is qualified for elevated working pressures. And like with ball valves, compatibility with other hydrogen-qualified components is a must.

Hydrogen Check Valves

Hydrogen Check Valves

Check valves perform essential safety functions in hydrogen compressors in refueling systems, controlling excess backflow in order to protect the end user. Compared with general service applications, hydrogen check valves must contend with a few things.

Most check valves incorporate springs—components that are typically made with strain hardened material that can be more susceptible to hydrogen embrittlement than high-quality 316 stainless steel. Additionally, vehicle fueling applications subject such valves to large, fast changes in temperature and pressure, creating elevated stress on the valve’s elastomer seals. With these things in mind, ball check valves are a more suitable option for hydrogen compressors. Material integrity and compatibility with other hydrogen components are important here, too.

***

The long-term viability of hydrogen mobility fuel market depends on the safety, reliability, and durability of vehicles and infrastructure. Selecting and specifying the right components for all hydrogen systems can help the technology meet its full potential over the long term.

Interested in learning more? Swagelok offers a range of ball, needle, and check valves suitable for hydrogen service, along with a complete portfolio of additional components that can help make your hydrogen systems safer and more reliable. Our hydrogen specialists are happy to help you choose wisely and find a solution that meets your needs.

Related Articles

The Anatomy of a Hydrogen Fitting

Learn why fittings designed specifically for hydrogen applications can help fuel cell vehicle OEMs and infrastructure developers achieve safer and more reliable fuel systems.

On the Frontier of Hydrogen Transportation

Find out how advanced fitting technology helps the Swiss government improve hydrogen fuel cell vehicles and promote clean mobility.

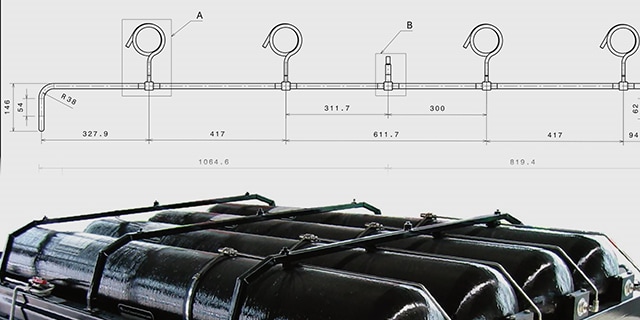

Luxfer Hydrogen Fuel Cell Case Study

Swagelok’s spirit of collaboration and willingness to invest in an EC-79 certification enabled Luxfer to create fuel delivery systems to power 144 hydrogen fuel cell buses. Learn how Swagelok Manchester’s level of commitment drove innovation for Luxfer.