“I’m under pressure to design and support fluid systems that operate safely.”

Safety may be a high priority, but accidents could still happen. Industrial fluid systems often transport high-pressure and high-temperature fluids, and a single leak or suboptimal design could trigger significant health, safety, and environmental risks. Up to 42% of plant-related safety incidents are preventable, and the right approach to safe fluid system design can protect people and profitability.

Our Solution: We offer fluid system troubleshooting services designed to find and measure existing leaks and identify potential failure points before damage or injury occurs. Work with Swagelok experts to mitigate risks and prioritize fluid system safety improvements.

“I’m under pressure to improve the efficiency and overall health of my fluid systems.”

High-quality, accurate fluid system outputs are crucial to customer satisfaction, meaning your systems must run optimally and cost-effectively at all times. Suboptimal designs, improper material choice, or installation issues can threaten the performance of your fluid systems, so it is worth taking the time to consider whether you could achieve better fluid system results.

Our Solution: We provide fluid system evaluation and optimization services services that draw upon our team’s deep knowledge of system design, materials science, and installation best practices to help you build better fluid systems. Receive guidance from seasoned fluid system professionals on the best ways to design and construct systems that will provide the performance you need.

“I’m under pressure to constantly balance resources to meet the needs of my business.”

Whether you’re dealing with an upturn in production, urgent customer demands, or shrinking budgets, there are many reasons you might feel like you can’t keep up. Even a small delay can reduce profitability, putting pressure on you. You need support to design, fabricate, and maintain systems on time and on budget.

Our Solution: We provide design consultation and assembly services meant to take strain off you. If you’re short on manpower, Swagelok can provide an extra set of hands by building your fluid system assemblies for you, or we can work with you to develop customized solutions to your challenges.

Learn more about locally available support.

You know Swagelok as a trusted supplier of high-quality fluid system components. But we can also help you alleviate some of the operational and maintenance-related pressures you face. Interested in learning more? Fill out the service request form linked below for more information.

Dig deeper. Explore resources developed for professionals like you.

7 Tips for Building Safer Industrial Fluid Systems

From not mixing components to reducing design complexity and accounting for vibration/movement, these are seven factors to remember as you create your fluid systems.

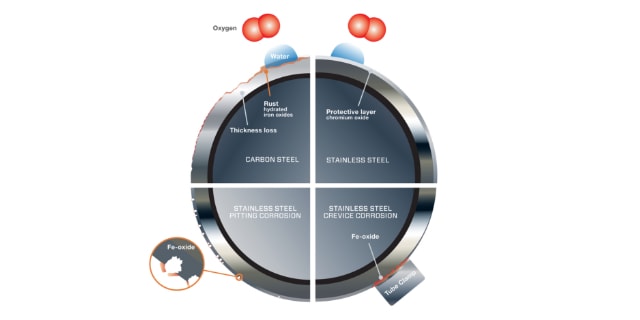

Material Matters: Selecting the Right Material for Corrosion Resistance

There are many factors that can affect whether or not corrosion plagues your systems. Know how to pick the right metals for your applications, and ask the right questions for quality control.

How Fluid System Fabrication Can Alleviate Resource Constraints

Outsourcing some common, but critical, fabrication and assembly work can help you get more done when resources are scarce. When looking for a fabricator, these considerations can help you make the best choice.